Why throw away steam that you have already paid for?

Customers may not realize the huge amount of energy that is LOST through small steam vents in your heating system or steam process. 950 btus per pound of steam is lost when steam is vented. Recovering that energy can significantly reduce the load on your boiler system and significantly reduce your fuel cost $$.

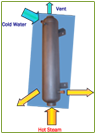

Cannon has a line of vent condensers, three different designs, that can recover heat energy and recycle it back into your system.

Cannon has the standardized VC-7 unit in-stock and ready for shipment. This unit handles up to 1000lb/hr of vented steam, and up to 20GPM of cold water flow used to collapse the steam and capture the energy. The included chart shows the performance of this unit at various suggested flow rates.

Cannon can design and manufacture custom vertical shell & tube units for higher steam flow rates, up to 10,000 lb/hr. Remember that you must have one gallon of water to collapse every 74 pounds of vented steam (water flow is 7 times higher steam flow to collapse all of the steam), so check your available water usage to validate the installation of a condenser.

TMC Application

The Cannon Ultramizer TMC recovers moisture and heat from not only clean combustion gasses but also other clean moist air streams. The inherent qualities of the Transport Membrane Condenser tubes allow water to pass through the tube wall and combine with the cooling water flowing through the ID of the tube. The water does not require further treatment, and is pH neutral.

This system is designed for clean burning fuels such as natural gas or propane.

Cannon Boiler Works, Inc.

510 Constitution Blvd., New Kensington, PA 15068

P: 724.335.8541 F: 724.335.6511

sales@cannonboilerworks.com